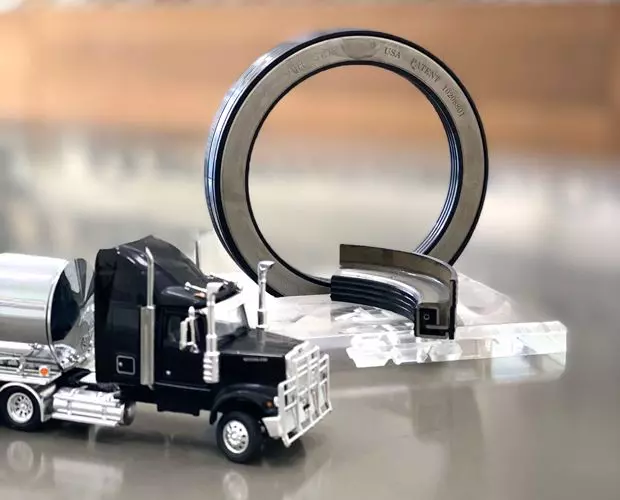

PTFE Lip Seals

PTFE rotary shaft seals were first introduced in the early 1970’s as crankshaft seals for diesel engines. Crankshaft seals were traditionally a difficult application for rubber seals due to a combination of speed, temperature and vibration. Since then many more applications have replaced rubber seals with PTFE seals as the benefits outweigh the initial extra cost.

The main reasons why PTFE seals are becoming more widely used is that they allow machinery to run faster, hotter and more efficient for longer. The low friction increases efficiency, and the low wear increase seal life far beyond what can be achieved with conventional rubber seal. PTFE seals also allow manufacturers to offer extended maintenance periods and extended warranties.

\

PTFE seals can be divided into three types:

1. Molded

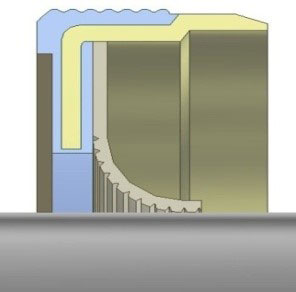

This type is the most common having superseded the majority of clamped design seals, particularly for engines, due to technical and cost benefits. The PTFE element is first etched, then bonded during the molding operation, ensuring a very secure static seal compared to the clamped designs. A selection of rubbers can be used to suit the application, but the most common is polyacrylic (ACM).

2. Clamped

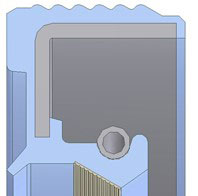

The clamped design offers many designs options, where small quantities can be produced with minimal tooling cost. These are now used mainly for smaller seals or where there is pressure, such as for compressors and small pumps. With this design, the PTFE is clamped between two shells, and a rubber gasket. The seal OD is usually metal, either ground or with a sealant applied.

3. Crimped-Solid body

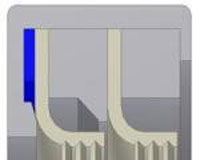

This design is used primarily for food, pharmaceutical applications and motorsports. The PTFE is fitted into a groove, then the metal crimped into the PTFE. Typical metal cases’ materials are Stainless Steel or Aluminum.

PTFE Lip Seals | Taiwan-Based E-Barrier Wheel Seals, Centurion Wheel Seals & AXLE/Cassette Seals Manufacturer For Over 30 Years | CHU HUNG OIL SEALS INDUSTRIAL CO., LTD.

Located in Taiwan since 1988, CHU HUNG OIL SEALS INDUSTRIAL CO., LTD. is a PTFE Lip Seals / oil seal manufacturer focusing on trucks, trailers, agricultural machinery and commercial vehicles. Main products, including automotive seals, industrial seals, truck seals, trailer seals, agricultural machinery seals, axle seals, hub seals, heavy duty seals, wheel seals, power steering seals, etc.

With more than 30 years of sealing technology experience, CHO is specialized in AXLE seals for trucks and trailers. ISO/TS 16949 certified 13,000 square meters plant size with rigorous QC tests, CHO oil seals including automotive seals, industrial seals, truck seals, trailer seals, agricultural machinery seals, axle seals, hub seals, heavy duty seals, wheel seals, power steering seals. Great oil and water resistance, high tensile strength oil seals | lip seals | axle seals are manufactured with materials, such as rubber, hydrogenated nitrile, fluorocarbon, silicone rubber and ethylene propylene diene rubber.

CHO has been offering customers high-quality seals since 1988, both with advanced sealing technology and 35 years of experience, CHO ensures each customer's demands are met.